28 Skills to Include in Your 2025 Manufacturing Systems Engineer Resume with Examples

As a Manufacturing Systems Engineer, having a robust skill set is essential to thrive in this dynamic and technologically advanced field. This section highlights the top skills that can enhance your resume and make you a standout candidate. From technical proficiencies to analytical capabilities, these skills are crucial for optimizing manufacturing processes, improving efficiency, and ensuring quality control. Let's explore the key competencies that can help you succeed in this role.

Best Manufacturing Systems Engineer Technical Skills

Technical skills are essential for a Manufacturing Systems Engineer as they enable professionals to design, implement, and optimize manufacturing processes effectively. These skills not only enhance productivity but also ensure quality and efficiency in production systems. Below are some of the top technical skills relevant to this role.

Process Improvement

Process improvement involves analyzing current manufacturing processes and identifying areas for enhancement to increase efficiency and reduce waste.

How to show it: Quantify your contributions by stating percentage improvements in efficiency or reductions in waste.

Lean Manufacturing

Lean manufacturing focuses on minimizing waste without sacrificing productivity, leading to streamlined operations and cost savings.

How to show it: Highlight specific lean initiatives you led and their resulting impact on cost savings or throughput.

Six Sigma

Six Sigma is a set of techniques and tools for process improvement, helping to reduce defects and enhance product quality.

How to show it: Mention certifications and any projects where you achieved significant quality improvements using Six Sigma methodologies.

CAD Software Proficiency

Proficiency in CAD software is crucial for designing and modeling production systems and components, enabling effective visualization of manufacturing setups.

How to show it: List specific CAD tools you are proficient in and any projects that required their use.

Manufacturing Execution Systems (MES)

MES are crucial for monitoring and controlling manufacturing operations in real-time, ensuring seamless production flow and data accuracy.

How to show it: Describe your experience with MES and how it improved operational efficiency or data integration.

Robotics and Automation

Knowledge of robotics and automation technologies is vital for enhancing production efficiency and reducing human error in manufacturing processes.

How to show it: Detail any automation projects you managed and the resultant improvements in speed or accuracy.

Data Analysis and Statistical Software

Data analysis skills allow engineers to interpret manufacturing data and make informed decisions based on statistical trends and patterns.

How to show it: Provide examples of data-driven decisions you made that led to measurable improvements in production.

Quality Control Techniques

Quality control techniques are essential for ensuring products meet specified standards and for reducing defects in manufacturing outputs.

How to show it: Quantify your impact on quality metrics or the reduction of defects through implemented control measures.

Supply Chain Management

Understanding supply chain management enables engineers to optimize procurement and logistics, ensuring materials are available for production when needed.

How to show it: Highlight any supply chain initiatives that led to cost reductions or improved lead times.

Project Management

Project management skills are critical for overseeing manufacturing projects, ensuring they are completed on time and within budget.

How to show it: Discuss specific projects you managed, focusing on timelines and budget adherence.

Simulation Software

Simulation software is used to model manufacturing processes, allowing engineers to predict performance and identify potential issues before implementation.

How to show it: Include examples of simulations you conducted and how they influenced design decisions or process changes.

Best Manufacturing Systems Engineer Soft Skills

In the field of manufacturing systems engineering, technical expertise is essential, but soft skills play a critical role in fostering collaboration, enhancing problem-solving capabilities, and driving project success. These skills help engineers effectively communicate their ideas, manage their time efficiently, and work cohesively within teams. Highlighting these skills on your resume can set you apart from other candidates and demonstrate your ability to thrive in a dynamic work environment.

Communication

Effective communication is key for Manufacturing Systems Engineers, as they must convey complex technical information clearly to diverse audiences.

How to show it: Include examples of presentations, reports, or team meetings where you facilitated understanding or shared critical information.

Problem-solving

The ability to identify issues and develop effective solutions is crucial in manufacturing environments where efficiency and precision are paramount.

How to show it: Quantify instances where you successfully resolved a manufacturing issue, detailing the impact on productivity or cost savings.

Time Management

Manufacturing Systems Engineers often juggle multiple projects and deadlines, making strong time management skills essential for prioritizing tasks effectively.

How to show it: Demonstrate your ability to meet deadlines by providing examples of projects completed on time and any tools used to manage your schedule.

Teamwork

Collaboration with cross-functional teams is vital in manufacturing, as engineers must work closely with other professionals to achieve common goals.

How to show it: Share experiences where you contributed to a team effort, highlighting your role and the project's outcome.

Attention to Detail

In manufacturing systems, attention to detail ensures that processes are followed accurately, minimizing errors and enhancing quality.

How to show it: Provide examples of how your meticulousness led to improved product quality or reduced waste.

Adaptability

The manufacturing landscape is continually evolving, requiring engineers who can quickly adapt to new technologies and processes.

How to show it: Illustrate your flexibility by sharing examples of how you successfully navigated changes or learned new systems.

Leadership

Even in non-managerial roles, leadership skills enable Manufacturing Systems Engineers to inspire and guide their peers toward achieving project objectives.

How to show it: Discuss instances where you took the initiative on a project or mentored a colleague, showcasing your leadership qualities.

Analytical Thinking

Analytical thinking allows engineers to systematically evaluate processes and data to make informed decisions that improve efficiency.

How to show it: Highlight specific projects where your analytical approach led to significant improvements or innovations.

Creativity

Creativity is essential for developing innovative solutions and improving existing manufacturing processes in a competitive industry.

How to show it: Provide examples of creative solutions you proposed and their successful implementation.

Conflict Resolution

Manufacturing environments can be high-pressure, making conflict resolution skills vital for maintaining a harmonious workplace.

How to show it: Share examples of situations where you successfully resolved conflicts and the positive outcomes that resulted.

Critical Thinking

Critical thinking enables engineers to evaluate situations logically and make sound decisions based on data and evidence.

How to show it: Provide examples of decisions made using critical thinking that led to improvements in manufacturing processes.

How to List Manufacturing Systems Engineer Skills on Your Resume

Effectively listing your skills on a resume is crucial for standing out to employers. It provides a snapshot of your qualifications and demonstrates your suitability for the role. There are three main sections where you can highlight your skills: Resume Summary, Resume Work Experience, Resume Skills Section, and Cover Letter.

for Resume Summary

Showcasing Manufacturing Systems Engineer skills in the introduction section gives hiring managers a quick overview of your qualifications and sets the tone for the rest of your resume.

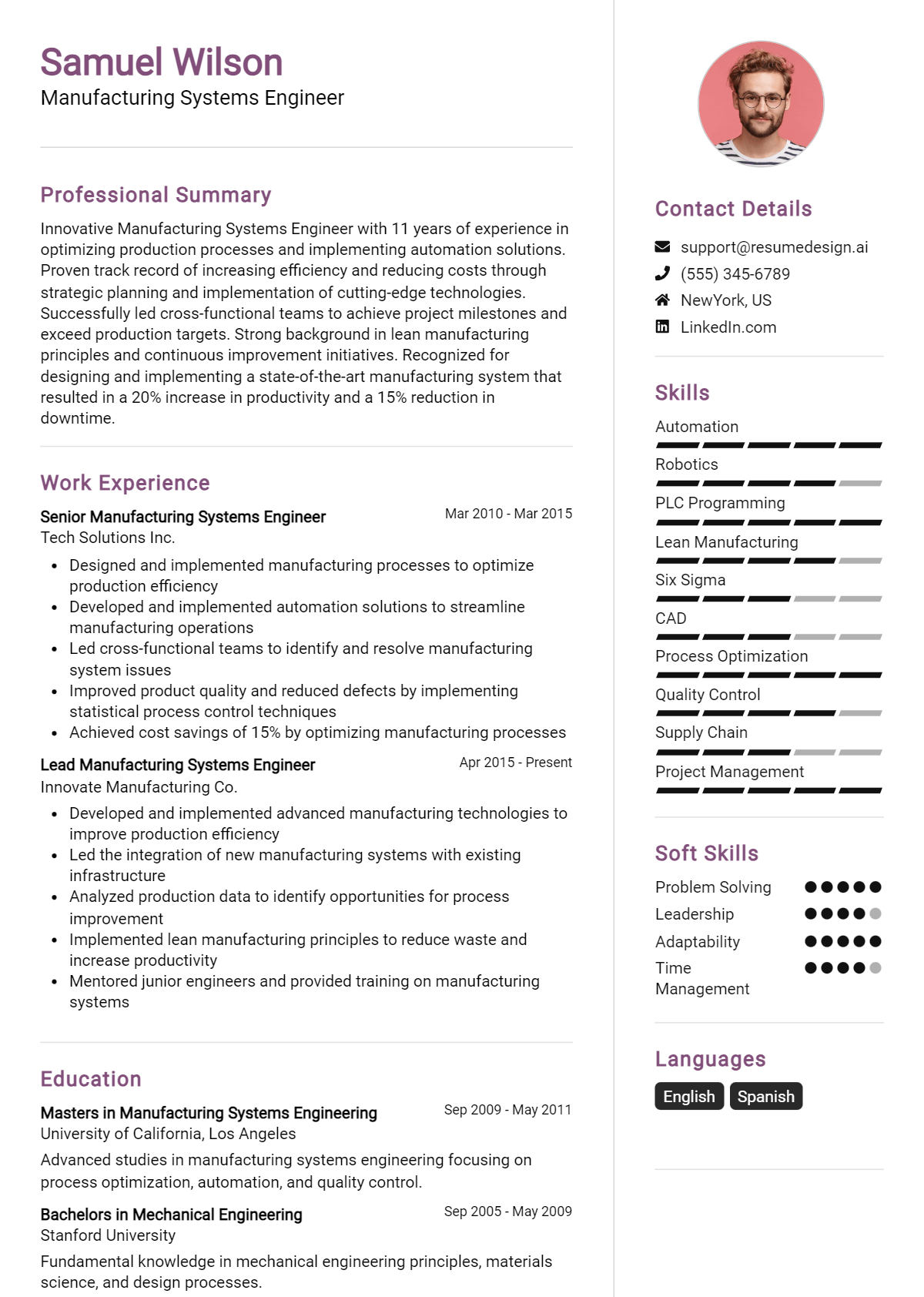

Example

As a Manufacturing Systems Engineer with expertise in process optimization and automation solutions, I have successfully implemented strategies that enhance productivity and reduce waste across production lines.

for Resume Work Experience

The work experience section is the perfect opportunity to demonstrate how your Manufacturing Systems Engineer skills have been applied in real-world scenarios, showcasing your impact on previous employers.

Example

- Leveraged Lean Manufacturing principles to reduce production costs by 15% through waste elimination.

- Designed and implemented automated systems, improving efficiency by 20% and enhancing overall production quality.

- Collaborated with cross-functional teams to optimize workflow processes, resulting in a 30% increase in throughput.

- Utilized data analysis tools to drive decision-making, leading to improved project timelines and resource allocation.

for Resume Skills

The skills section can showcase both technical and transferable skills. A balanced mix of hard and soft skills is essential to present a well-rounded profile.

Example

- Process Optimization

- Automation Solutions

- Lean Manufacturing

- Data Analysis

- Project Management

- Cross-Functional Collaboration

- Quality Assurance

- Industrial Engineering

for Cover Letter

A cover letter allows candidates to expand on the skills mentioned in the resume and provide a more personal touch. Highlighting 2-3 key skills that align with the job description can illustrate how they have positively impacted your previous roles.

Example

In my previous role, my expertise in Lean Manufacturing and process optimization led to a significant reduction in operational costs and improved production efficiency. I am eager to bring this experience to your team and drive similar results at your organization.

Linking the skills mentioned in your resume to specific achievements in your cover letter reinforces your qualifications for the job.

The Importance of Manufacturing Systems Engineer Resume Skills

Highlighting relevant skills in a Manufacturing Systems Engineer resume is crucial for making a strong first impression on potential employers. A well-crafted skills section not only showcases a candidate's technical proficiency and problem-solving capabilities but also demonstrates alignment with the job requirements. This targeted approach helps candidates stand out among the competition, increasing their chances of landing an interview.

- Manufacturing systems engineers must possess a diverse skill set that includes technical, analytical, and interpersonal skills. This variety enables them to tackle complex manufacturing challenges effectively and innovate processes to enhance productivity.

- Strong technical skills in areas such as CAD software, automation technologies, and process optimization are essential. Employers look for candidates who can seamlessly integrate modern technology into existing systems to improve efficiency and reduce costs.

- The ability to analyze data and make data-driven decisions is paramount in the manufacturing sector. Highlighting skills in statistical analysis and data interpretation showcases a candidate's capability to identify trends and implement improvements.

- Manufacturing systems engineers often work in cross-functional teams. Demonstrating strong collaboration and communication skills on a resume highlights the candidate's ability to work well with others to achieve common goals.

- Adaptability is another critical skill in the manufacturing industry, where technologies and methodologies are constantly evolving. Candidates should emphasize their willingness to learn and adapt to new technologies and processes to stay relevant.

- Project management skills are highly valued in manufacturing environments. A well-defined skills section that includes experience in managing projects from conception to completion can set candidates apart from their peers.

- Problem-solving abilities are at the core of a manufacturing systems engineer's role. Illustrating experience with troubleshooting and process improvement initiatives can effectively convey a candidate's capability to address challenges head-on.

- Employers often look for candidates with a strong understanding of lean manufacturing principles. Showcasing knowledge in methodologies like Six Sigma can enhance a candidate's appeal and demonstrate their commitment to operational excellence.

For more insights and examples, check out these Resume Samples.

How To Improve Manufacturing Systems Engineer Resume Skills

In the rapidly evolving field of manufacturing, it is crucial for Manufacturing Systems Engineers to continuously improve their skills to stay competitive and effective. As technology advances and industry standards change, honing your expertise not only enhances your resume but also boosts your performance and career growth. Here are some actionable tips to help you refine your skills:

- Engage in Continuous Learning: Enroll in relevant courses, workshops, or webinars to stay updated on the latest manufacturing technologies and methodologies.

- Gain Hands-On Experience: Participate in practical projects or internships that allow you to apply theoretical knowledge to real-world manufacturing scenarios.

- Network with Professionals: Connect with other manufacturing engineers through industry conferences, online forums, or local meetups to share insights and best practices.

- Obtain Certifications: Consider pursuing certifications such as Six Sigma, Lean Manufacturing, or PMP to validate your skills and enhance your credibility.

- Stay Informed on Industry Trends: Regularly read industry publications, journals, and blogs to keep abreast of new developments and emerging technologies in manufacturing.

- Develop Soft Skills: Work on communication, teamwork, and problem-solving abilities, as these are essential for collaboration and project management in manufacturing environments.

- Utilize Software Tools: Familiarize yourself with the latest manufacturing software and tools, such as CAD, ERP systems, and simulation software, to improve efficiency and productivity.

Frequently Asked Questions

What technical skills are essential for a Manufacturing Systems Engineer?

A Manufacturing Systems Engineer should possess a strong foundation in various technical skills, including proficiency in CAD software, knowledge of manufacturing processes, and experience with automation tools. Familiarity with industrial engineering principles, lean manufacturing techniques, and statistical process control is also crucial. Additionally, understanding systems integration and data analysis can significantly enhance the engineer's ability to optimize production efficiency and quality.

How important is problem-solving in this role?

Problem-solving is a critical skill for a Manufacturing Systems Engineer, as the role often involves identifying inefficiencies and developing solutions to complex manufacturing challenges. These engineers must analyze data, diagnose issues in production systems, and implement changes that enhance productivity while minimizing waste. Strong analytical skills, combined with creative thinking, enable them to devise innovative solutions that contribute to the overall success of manufacturing operations.

What role does communication play in a Manufacturing Systems Engineer's job?

Effective communication is vital for a Manufacturing Systems Engineer, as they frequently collaborate with cross-functional teams, including production staff, management, and quality assurance personnel. Clear communication helps ensure that everyone understands project objectives, timelines, and technical specifications. Additionally, the ability to convey complex technical information in an accessible manner is essential for facilitating training and gaining buy-in for process improvements.

What software tools are commonly used by Manufacturing Systems Engineers?

Manufacturing Systems Engineers commonly utilize a variety of software tools to aid in design, simulation, and data analysis. Popular tools include CAD software like AutoCAD or SolidWorks for design, ERP systems for resource planning, and simulation software such as Arena or AnyLogic for modeling manufacturing processes. Additionally, proficiency in data analysis tools like Excel, Minitab, or statistical software is important for analyzing production data and driving continuous improvement initiatives.

What experience is beneficial for a Manufacturing Systems Engineer?

Experience in manufacturing environments is highly beneficial for a Manufacturing Systems Engineer. This can include roles in production, quality control, or process improvement. Internships or co-op positions can also provide valuable hands-on experience. Familiarity with specific industry standards and regulations, as well as experience with project management methodologies, can further enhance an engineer's qualifications and readiness to tackle the challenges in manufacturing systems optimization.

Conclusion

Including the skills of a Manufacturing Systems Engineer in your resume is crucial for demonstrating your technical expertise and problem-solving capabilities to potential employers. By effectively showcasing relevant skills, you not only stand out from other candidates but also provide tangible value that aligns with the needs of the organization. Remember, the more you refine your skills and tailor your application, the better your chances of landing that dream job. So, take the initiative to enhance your expertise and make your resume shine!

For more resources, check out our resume templates, utilize our resume builder, explore various resume examples, and craft compelling cover letter templates to elevate your job application process.

Use an AI-powered resume builder and have your resume done in 5 minutes. Just select your template and our software will guide you through the process.