22 Hard and Soft Skills to Put On Lean Manufacturing Engineer Resume for 2025

As a Lean Manufacturing Engineer, having the right skill set is crucial to successfully driving efficiency and improvement within manufacturing processes. This section highlights the top skills that you should consider including on your resume. These skills not only demonstrate your expertise in lean principles but also showcase your ability to implement effective solutions that reduce waste and enhance productivity in a manufacturing environment.

Best Lean Manufacturing Engineer Technical Skills

Technical skills are crucial for Lean Manufacturing Engineers as they directly impact efficiency, productivity, and waste reduction in manufacturing processes. Highlighting these skills on your resume can demonstrate your ability to implement lean principles effectively and contribute to continuous improvement initiatives.

Value Stream Mapping

Value Stream Mapping is a visual tool that helps identify waste and areas for improvement in the manufacturing process. It is essential for understanding workflow and optimizing operations. How to show it: Include examples of how you used Value Stream Mapping to reduce cycle time or improve process efficiency.

Six Sigma Methodologies

Six Sigma methodologies focus on reducing defects and improving quality through data-driven decision-making. This skill is vital for ensuring high standards in manufacturing processes. How to show it: Quantify improvements achieved through Six Sigma projects, such as percentage reductions in defects or cost savings.

Kaizen Implementation

Kaizen is a continuous improvement philosophy that emphasizes small, incremental changes to enhance productivity and efficiency. Mastery of Kaizen can lead to substantial long-term improvements. How to show it: Detail specific Kaizen events you led and the measurable results, like improved throughput or reduced waste.

Root Cause Analysis

Root Cause Analysis is a systematic approach to identifying the underlying causes of problems in manufacturing processes, which is critical for implementing effective solutions. How to show it: Provide examples of problems resolved through Root Cause Analysis, highlighting the impact on production quality or efficiency.

Standard Work Procedures

Developing and implementing Standard Work Procedures ensures consistency in operations and helps maintain quality and efficiency. This skill is essential for training and developing team members. How to show it: Describe how you created or improved Standard Work Procedures, including measurable increases in efficiency or reductions in errors.

Lean Tools and Techniques

Proficiency in various Lean tools such as 5S, Kanban, and Poka-Yoke is vital for streamlining processes and minimizing waste. How to show it: List specific Lean tools you have implemented and the positive outcomes, such as reduced lead times or improved safety.

Data Analysis and Reporting

Strong data analysis skills allow Lean Manufacturing Engineers to track performance metrics and identify improvement opportunities based on empirical evidence. How to show it: Highlight your experience with data analysis tools and how your insights led to significant operational improvements.

Project Management

Effective project management skills are essential for leading lean initiatives, ensuring that projects are completed on time and within budget while meeting quality standards. How to show it: Mention successful lean projects you led, including timelines, budgets, and results achieved.

Cross-Functional Collaboration

The ability to work across various departments is crucial for successfully implementing lean strategies and fostering a culture of continuous improvement. How to show it: Provide examples of successful cross-functional projects, emphasizing team collaboration and outcomes.

Change Management

Change management skills are important for guiding teams through transitions related to lean initiatives, ensuring buy-in and minimizing resistance to change. How to show it: Describe how you facilitated change management in lean projects, focusing on employee engagement and performance improvements.

Process Optimization

Expertise in process optimization involves analyzing workflows to improve efficiency and reduce waste, which is a core principle of lean manufacturing. How to show it: Quantify process improvements you achieved, such as reductions in cycle time or increases in output.

Best Lean Manufacturing Engineer Soft Skills

In the field of Lean Manufacturing, possessing strong soft skills is just as critical as technical expertise. These skills enable Lean Manufacturing Engineers to effectively collaborate, communicate, and problem-solve within teams, ultimately driving efficiency and continuous improvement in manufacturing processes. Here are some essential soft skills to highlight on your resume:

Communication

Clear and concise communication is vital for Lean Manufacturing Engineers to facilitate discussions with team members, stakeholders, and management.

How to show it: Demonstrate your communication skills by citing specific projects where your communication led to successful outcomes or improved team dynamics.

Problem-solving

Lean Manufacturing Engineers must identify issues and devise effective solutions to enhance processes and eliminate waste.

How to show it: Highlight instances where you successfully resolved a complex issue, including metrics that showcase the positive impact of your solution.

Teamwork

Collaboration is essential in Lean methodologies, as engineers often work alongside cross-functional teams to implement improvements.

How to show it: Provide examples of successful team projects, noting your role and how your contributions helped achieve team goals.

Time Management

Effective time management allows Lean Manufacturing Engineers to prioritize tasks and meet project deadlines without sacrificing quality.

How to show it: Detail how you have optimized timelines in past projects, using specific examples of deadlines met or exceeded.

Adaptability

The ability to adapt to changing circumstances is crucial in the fast-paced manufacturing environment, where priorities can shift rapidly.

How to show it: Describe situations where you successfully adjusted to changes in project scope or processes, emphasizing the outcomes achieved.

Critical Thinking

Critical thinking enables Lean Manufacturing Engineers to analyze situations and make informed decisions based on data and evidence.

How to show it: Illustrate your critical thinking skills by discussing decisions made based on data analysis that led to improved processes.

Leadership

Leadership skills help Lean Manufacturing Engineers guide teams and initiatives, fostering a culture of continuous improvement.

How to show it: Provide examples of leadership roles or initiatives you've undertaken, focusing on team or project successes.

Attention to Detail

Attention to detail is essential for identifying inefficiencies and ensuring that processes are followed correctly.

How to show it: Share instances where your attention to detail prevented errors or led to significant improvements in quality or efficiency.

Conflict Resolution

The ability to resolve conflicts effectively is important for maintaining a positive working environment and ensuring project success.

How to show it: Discuss specific conflicts you have mediated and the positive outcomes that resulted from your intervention.

Creativity

Creativity is essential for developing innovative solutions to manufacturing challenges and improving processes.

How to show it: Provide examples of creative solutions you've implemented that enhanced efficiency or quality in the manufacturing process.

Interpersonal Skills

Strong interpersonal skills allow Lean Manufacturing Engineers to build effective relationships with colleagues and stakeholders.

How to show it: Highlight experiences where your interpersonal skills contributed to successful collaborations or stakeholder engagement.

How to List Lean Manufacturing Engineer Skills on Your Resume

Effectively listing your skills on a resume is crucial for standing out to employers in a competitive job market. By clearly showcasing your qualifications, you can capture the attention of hiring managers. There are three main sections where you can highlight your skills: Resume Summary, Resume Work Experience, Resume Skills Section, and Cover Letter.

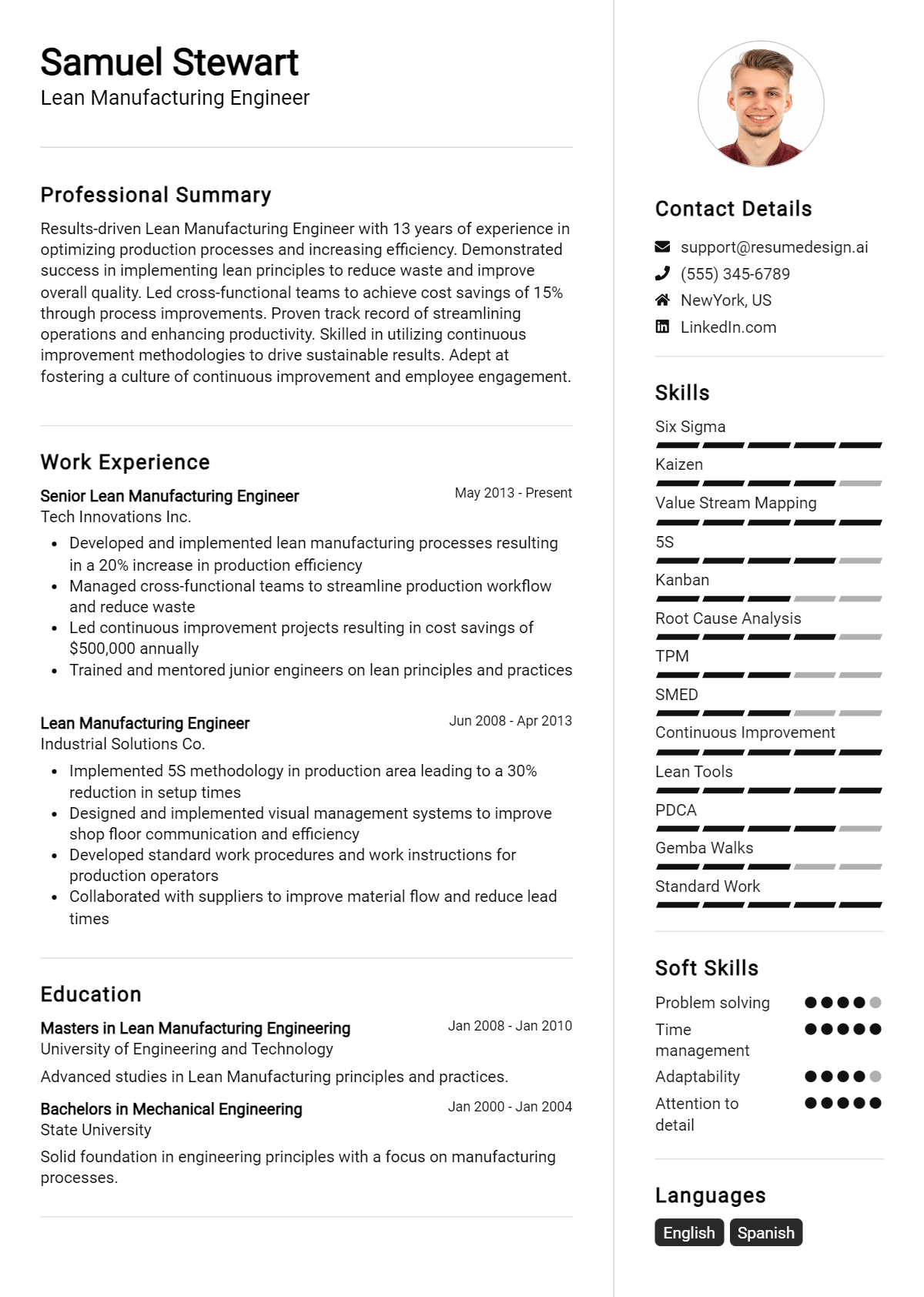

for Resume Summary

Highlighting your Lean Manufacturing Engineer skills in the summary section provides hiring managers with a quick overview of your qualifications and sets the tone for the rest of your resume.

Example

Lean Manufacturing, Six Sigma, and process improvement expertise with over 5 years of experience in optimizing production processes, enhancing efficiency, and driving quality improvements in a fast-paced manufacturing environment.

for Resume Work Experience

The work experience section is the perfect opportunity to demonstrate how your Lean Manufacturing Engineer skills have been applied in real-world scenarios, showcasing your contributions and achievements.

Example

- Implemented lean methodologies that resulted in a 20% reduction in production time.

- Led a Six Sigma project, achieving a 15% decrease in defects and improving overall product quality.

- Collaborated with cross-functional teams to develop process optimization strategies that increased workflow efficiency.

- Trained staff on continuous improvement techniques, fostering a culture of quality and accountability.

for Resume Skills

The skills section can showcase both technical and transferable skills. A balanced mix of hard and soft skills will strengthen your overall qualifications as a Lean Manufacturing Engineer.

Example

- Lean Manufacturing

- Six Sigma Certification

- Process Improvement

- Root Cause Analysis

- Project Management

- Team Leadership

- Data Analysis

- Problem Solving

for Cover Letter

A cover letter allows you to expand on the skills mentioned in your resume and provides a more personal touch. Highlighting 2-3 key skills that align with the job description can demonstrate how those skills have positively impacted your previous roles.

Example

With expertise in Lean Manufacturing and process improvement, I successfully led initiatives that reduced waste by 25% in my previous role. My ability to foster collaboration among teams has consistently resulted in achieving operational goals while maintaining high-quality standards, directly contributing to increased profitability.

Linking the skills mentioned in your resume to specific achievements in your cover letter reinforces your qualifications for the job and makes your application more compelling.

The Importance of Lean Manufacturing Engineer Resume Skills

Highlighting relevant skills in a Lean Manufacturing Engineer's resume is crucial for capturing the attention of recruiters and effectively aligning oneself with the specific job requirements. A well-crafted skills section not only showcases a candidate's qualifications but also demonstrates their understanding of lean principles and methodologies, making it easier for hiring managers to assess their fit for the role. By emphasizing the right skills, candidates can stand out in a competitive job market, increasing their chances of landing an interview.

- Demonstrates Expertise: Including specific lean manufacturing skills clearly illustrates a candidate's expertise in the field, showcasing their ability to implement lean principles effectively within an organization.

- Aligns with Job Requirements: By tailoring the skills section to match the job description, candidates can ensure they meet the essential qualifications outlined by employers, enhancing their chances of being shortlisted.

- Highlights Problem-Solving Abilities: Skills such as root cause analysis and continuous improvement reflect a candidate's capacity to identify and solve production issues, an essential trait for any Lean Manufacturing Engineer.

- Showcases Adaptability: Skills related to various lean tools and methodologies, such as Kaizen or Six Sigma, indicate a candidate's versatility and readiness to adapt to different manufacturing environments and challenges.

- Enhances Communication Skills: Proficiency in lean manufacturing often requires effective communication and teamwork. Highlighting these skills can demonstrate a candidate's ability to collaborate with cross-functional teams.

- Indicates Commitment to Efficiency: Skills focused on waste reduction and process optimization signal a candidate's dedication to enhancing operational efficiency, which is a core objective of lean manufacturing.

- Supports Career Advancement: A strong skills section can position candidates for future opportunities within the organization, as it reflects their potential for growth and contribution to lean initiatives.

For more examples and insights on effective resume creation, explore the Resume Samples.

How To Improve Lean Manufacturing Engineer Resume Skills

In the ever-evolving field of manufacturing, it is essential for Lean Manufacturing Engineers to continuously enhance their skills to remain competitive and effective. As companies strive for increased efficiency and reduced waste, professionals in this role must stay updated on the latest methodologies, tools, and technologies. Improving your skill set not only boosts your resume but also contributes to your overall professional development and success in the industry.

- Participate in Lean Six Sigma certification programs to deepen your understanding of process improvement methodologies.

- Engage in workshops and training sessions focused on the latest industry technologies and software relevant to lean manufacturing.

- Join professional organizations and networks to connect with other professionals and share best practices.

- Stay current with industry trends by reading relevant publications, attending conferences, and following thought leaders in lean manufacturing.

- Gain hands-on experience by volunteering for projects that allow you to apply lean principles in real-world scenarios.

- Seek feedback from peers and mentors to identify areas for improvement and refine your existing skills.

- Practice problem-solving techniques and data analysis to enhance your decision-making abilities in lean environments.

Frequently Asked Questions

What are the essential skills for a Lean Manufacturing Engineer?

A Lean Manufacturing Engineer should possess strong analytical skills to identify inefficiencies and waste in production processes. Proficiency in Lean methodologies such as 5S, Kaizen, and Value Stream Mapping is crucial. Additionally, effective problem-solving abilities, teamwork, and communication skills are vital to collaborate with various departments and implement improvements successfully.

How important is knowledge of Six Sigma for a Lean Manufacturing Engineer?

Knowledge of Six Sigma is highly beneficial for a Lean Manufacturing Engineer as it complements Lean principles by focusing on reducing variability and improving process quality. Familiarity with Six Sigma tools and techniques allows engineers to analyze data effectively, streamline operations, and enhance product quality, making them more effective in their roles.

What role does data analysis play in Lean Manufacturing?

Data analysis plays a critical role in Lean Manufacturing as it helps engineers identify trends, measure performance, and pinpoint areas for improvement. By utilizing data analytics tools, Lean Manufacturing Engineers can make informed decisions, track the effectiveness of implemented changes, and continuously refine processes to achieve optimal efficiency.

Can you explain the significance of cross-functional teamwork in Lean Manufacturing?

Cross-functional teamwork is significant in Lean Manufacturing as it fosters collaboration between different departments, such as production, quality, and supply chain. By working together, teams can share insights and perspectives, leading to more comprehensive solutions for process improvements. This collaborative approach enhances communication and ensures that lean initiatives are effectively integrated across the organization.

What certifications can enhance a Lean Manufacturing Engineer's resume?

Certifications such as Lean Six Sigma Green Belt or Black Belt, Certified Lean Practitioner, and ASQ Certified Quality Engineer can significantly enhance a Lean Manufacturing Engineer's resume. These certifications demonstrate a commitment to professional development and provide evidence of expertise in Lean principles and practices, making candidates more competitive in the job market.

Conclusion

Incorporating Lean Manufacturing Engineer skills in a resume is crucial for demonstrating your expertise and commitment to efficiency and continuous improvement. By effectively showcasing these relevant skills, candidates not only stand out in a competitive job market but also highlight the value they can bring to potential employers looking to enhance their processes and reduce waste. Remember, refining your skills and presenting them effectively can significantly improve your job application. Take the time to invest in your professional development and make your resume shine!

For additional resources to help you create an impressive application, explore our resume templates, utilize our resume builder, check out resume examples, and find the perfect format with our cover letter templates.

Use an AI-powered resume builder and have your resume done in 5 minutes. Just select your template and our software will guide you through the process.